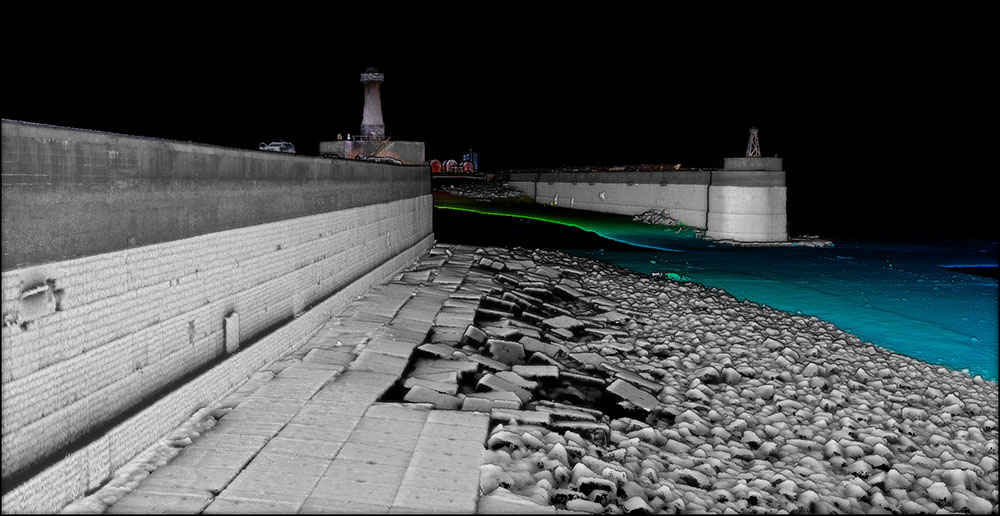

Peterhead Port, located on Scotland’s northeast coast, is home to one of the UK’s most historically significant maritime structures: two large vertical outer breakwaters totalling 1300m in length, in depths of up to 20mCD.

Constructed between 1892 and 1956 to form a harbour of refuge, these breakwaters protect the port from the full impact of the North Sea. With portions now over a century old, the structures remain critical to day-to-day port operations, and their preservation is essential to ensuring the port’s continued functionality and success.

Image courtesy of Peterhead Port Authority

To evaluate the structural condition and integrity of the breakwaters beneath the waterline, Peterhead Port Authority has maintained a partnership spanning over three decades with engineering consultancy

NIRAS, which has more recently engaged the expertise of high-resolution hydrographic specialists,

Ultrabeam Hydrographic.

Andrew Walker, Associate Director at NIRAS, explains why undertaking this hydrographic survey work is so important:

“It means Peterhead Port Authority, as a diligent custodian, can take informed and proactive decisions regarding the ongoing maintenance and life extension of these historic breakwater structures.

If one of these structures were to fail, it could potentially cost the Port millions of pounds to remediate and incur additional millions of pounds in lost revenue due to the port being inactive. Whilst it's neither cheap nor straightforward to maintain the structures, it's certainly cheaper and easier than that eventuality.”

A Structure Unlike Any Other

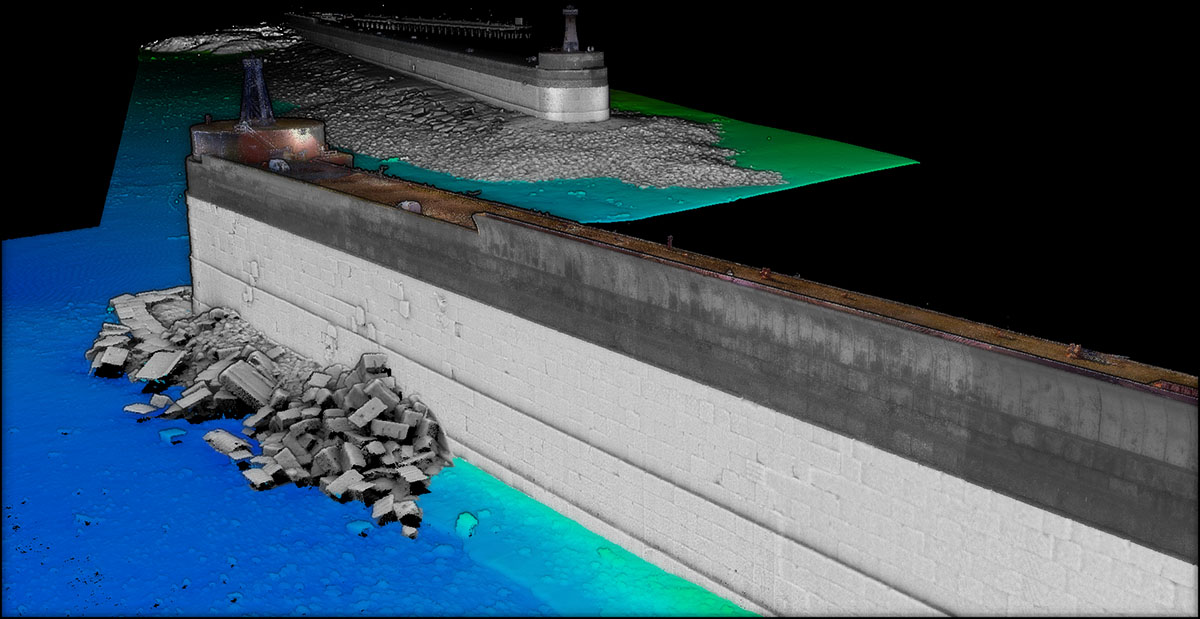

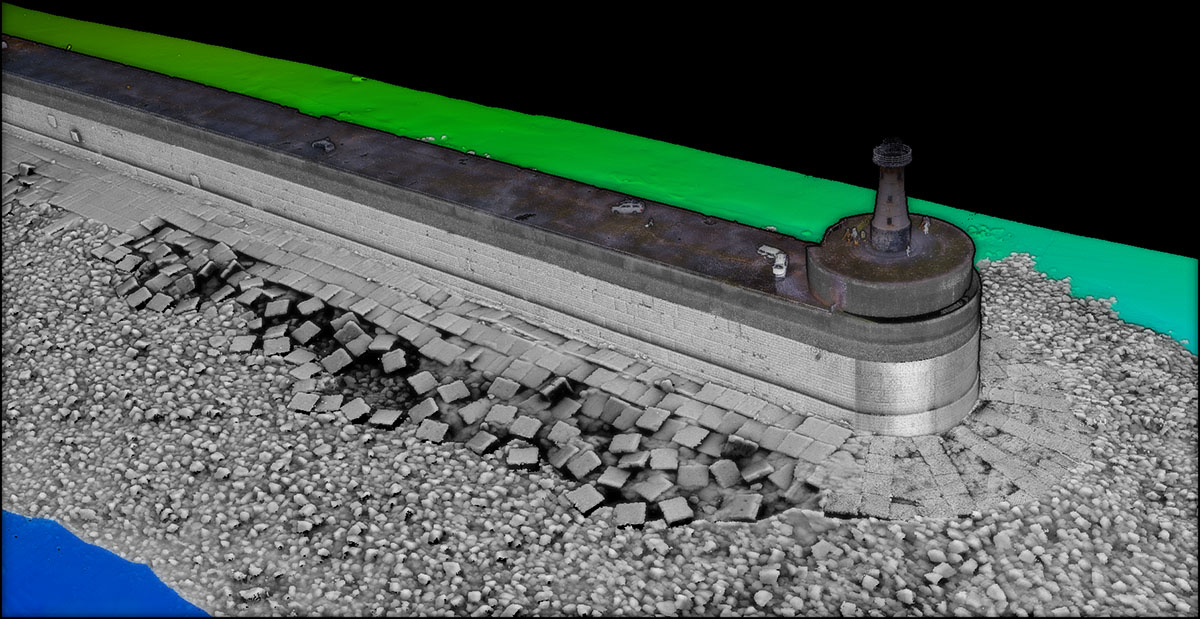

“This isn’t your typical rubble mound,” said Walker. “The Peterhead breakwater is built from massive, interlocking concrete blocks — more like Lego than loose rock. The south breakwater is founded on a mound protected from scour by 50t blocks, and some of those blocks have been shifting over time.”

“This isn’t your typical rubble mound,” said Walker. “The Peterhead breakwater is built from massive, interlocking concrete blocks — more like Lego than loose rock. The south breakwater is founded on a mound protected from scour by 50t blocks, and some of those blocks have been shifting over time.”

Because the structure is foundational to port operations, early detection of movement is critical. To obtain the necessary data for NIRAS’ integrity assessments, Walker tasked Gabriel Walton and the Ultrabeam team with conducting an advanced hydrographic survey. Given the need for exceptionally precise and high-resolution results, Teledyne Marine’s

SeaBat T51-R multibeam echosounder was chosen for the project.

The goal was clear: capture accurate, high-resolution, engineering-grade hydrographic data. The challenge, however, was considerable given the acoustically complex environment of Peterhead Port.

The breakwater’s underwater structure presents unique acoustic difficulties for sonar. Constructed from large, tightly interlocking granite blocks with sharp edges, steep vertical faces, and irregular cavities, the structure reflects sonar signals in unpredictable ways.

This often results in multipath interference, where sound waves bounce between surfaces before returning, leading to distorted or noisy data. Further complicating the environment are marine growth, historic construction debris and the highly reflective vertical surfaces, all of which can obscure or degrade sonar readings.

For NIRAS and Ultrabeam, Peterhead was a clear example of why project-specific planning and high-specification technology — in this case, the

SeaBat T51-R — are essential to acquiring reliable, actionable results.

Ultrabeam: Specialists in Ultra-High-Resolution Surveys

Ultrabeam, known for their specialist work in capturing extreme detail in ports, harbour walls, and bridge structures, was well-suited to the Peterhead project. Their niche lies in delivering ultra-high-resolution hydrographic data for infrastructure where clarity, precision, and repeatability are essential.

With particular experience in mapping vertical and complex structures, Ultrabeam’s focus is on delivering data that enables engineers to make confident, informed decisions about critical assets.

This project marked their first use of the

Teledyne SeaBat T51-R, chosen for its ability to deliver dense, high-quality, clean data with minimal false detections on both seabeds and challenging vertical marine structures.

Surveying a Complex Site with Confidence

The Peterhead survey took place in early 2025, after delays caused by severe weather. Once conditions improved, Ultrabeam responded quickly, navigating not only a narrow weather window but also the intricacies of the breakwater’s underwater topography.

“It’s a tough environment,” said Ultrabeam’s Walton.

“But we were really impressed with the

SeaBat T51-R performance. The data was exceptionally clean, and its high frequency full-swath width capability meant we could efficiently cover significantly larger areas of the seabed and vertical surfaces.”

The

SeaBat T51-R operates at 800 kHz, enabling high-resolution coverage across wide areas without sacrificing detail. For Ultrabeam, this meant fewer passes, faster data collection, reduced survey time and much less manual cleaning in post-processing — all while maintaining the ultra-high resolution required for this structural assessment.

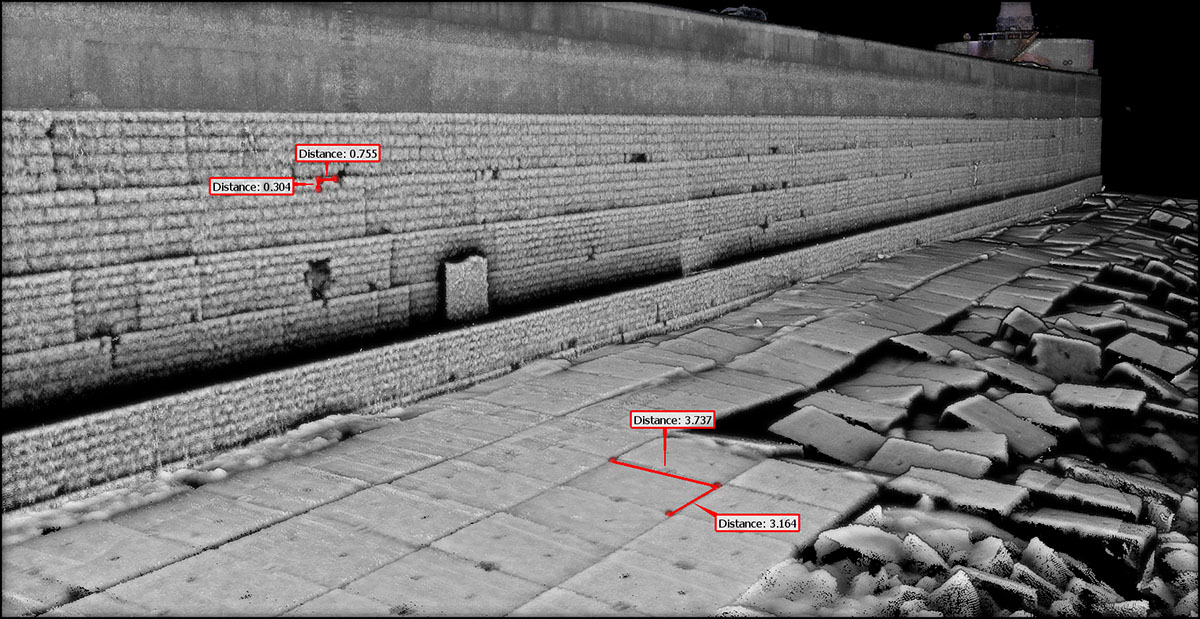

In recent surveys, precise measurements revealed that one block was slowly protruding from the vertical breakwater wall — something that had not been visible in earlier inspections. Thanks to the consistently improving quality of the data, targeted intervention was possible before any failure occurred.

Engineered for Results

Key features of the

SeaBat T51-R helped overcome the specific challenges of the Peterhead site:

-

Vertical detection mode delivered clear data on quay walls and vertical block faces.

-

Multipath corner suppression improved accuracy in noisy areas with complex geometry.

-

Automated acoustic gates removed unwanted noise before it entered the processing workflow.

“We used to make multiple passes in corners and clean them manually,” Walton explained.

“This time, the data was usable from the start. We could trust what we were seeing.”

Ultrabeam combined the sonar data with topside laser scanning to generate complete 3D models from seabed to surface, giving NIRAS a continuous visual record and quantitative data set of the structure and its condition to form the basis for detailed integrity assessments.

Turning Data into Action

The clarity of the data was key to decision-making.

“With this kind of survey, we can compare results year on year — or even against data from 20 years ago,” said NIRAS’ Walker.

“That allows us to identify patterns, understand structural trends, and plan maintenance accordingly.”

Instead of blanket repair campaigns, NIRAS, on behalf of Peterhead Port Authority, can now deploy divers to targeted locations, reduce unnecessary spend, and focus effort where it’s truly needed. “It’s smarter, safer, and more cost-effective,” Walker added.

Following the successful survey, Ultrabeam confirmed the

SeaBat T51-R will play a key role in future projects.

“It’s going to be a core part of our toolkit going forward,” said Walton.

“The better the data, the better the decisions — and this project proved that.”

Summary

The Peterhead breakwater project shows how advanced sonar systems like the

Teledyne SeaBat T51-R can bring clarity to even the most complex underwater structures, turning high-resolution data into targeted action. In critical infrastructure like ports, this kind of insight isn’t just valuable, it’s essential, helping to avoid potentially costly and hazardous failures.

With a proactive port authority, experienced engineers, and cutting-edge survey tools, this collaboration provides a clear example of what is possible in modern marine infrastructure maintenance.

Pim Kuus, Senior Hydrographer and Product Manager at Teledyne Marine, says,

“The SeaBat T51-R proved to be an ideal fit for Peterhead Port Authority, NIRAS and Ultrabeam, aligning with their objectives and addressing shared challenges — particularly in delivering high-quality data through simple and automated controls. What’s especially compelling is how pushing the boundaries of repeatable and precise measurement is enabling deeper insights into the condition of critical subsea assets. In the face of increasingly extreme weather events driven by climate change and the ongoing ageing of infrastructure, this kind of data has never been more vital.”