In the offshore oil and gas sector, where safe operations, operational efficiency, and enhanced safety are paramount, the importance of Acoustic Doppler Current Profilers (ADCP) on oil platforms cannot be overstated. The Pinnacle ADCP by Teledyne Marine RD Instruments (RDI) is an excellent example of state-of-the-art oceanographic instrumentation used in oil rig operations in the world’s oceans.

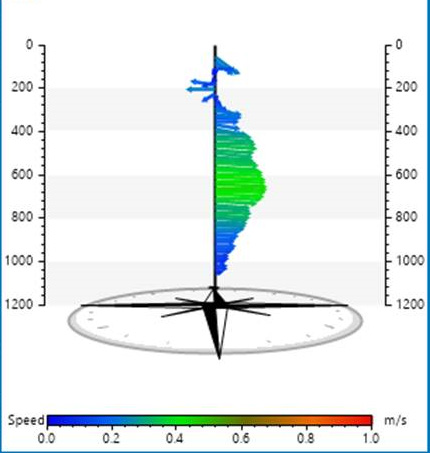

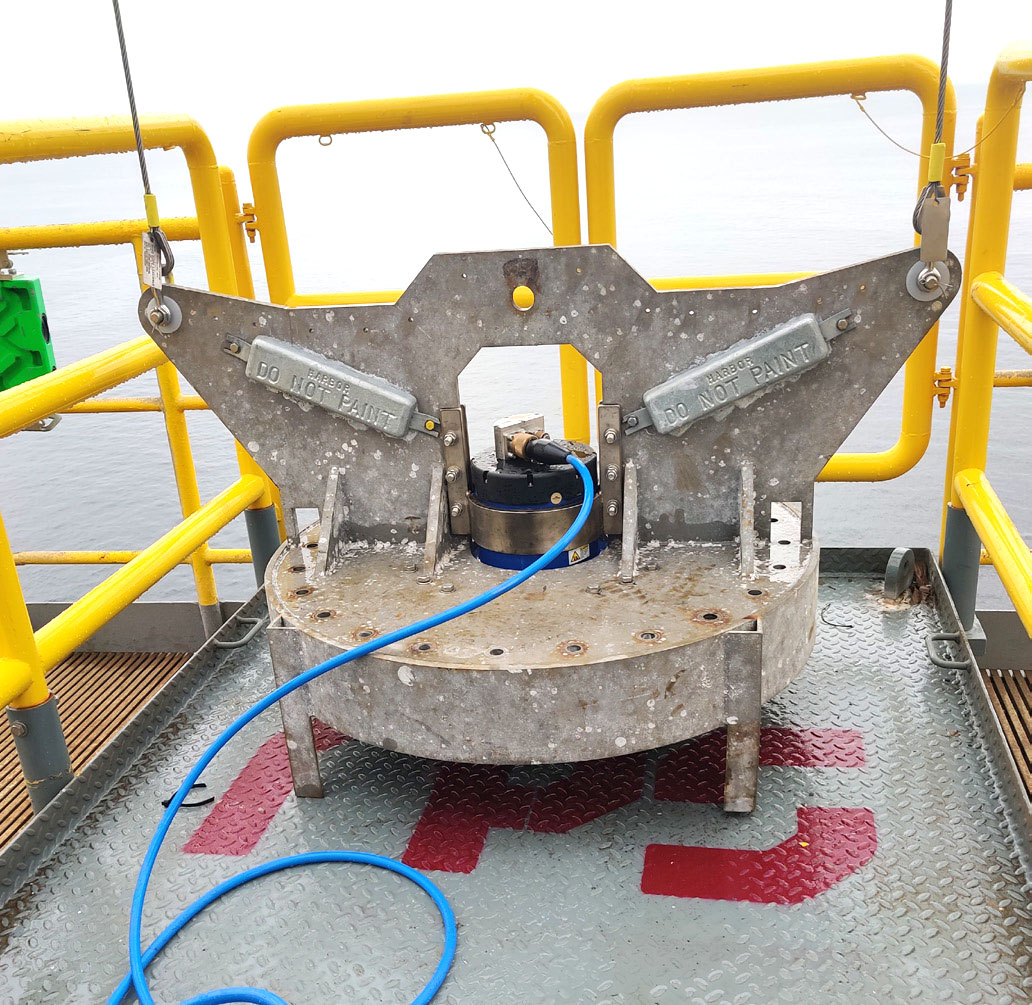

The Pinnacle ADCP facilitates time-series collection from near surface to up to 1000-meter depth coverage used by oil rig operators to monitor and plan the dynamics of deep-water currents around oil rigs. For example, in 2023, RDI and RPS (Tetra Tech), a UK engineering consultancy, installed a Pinnacle ADCP on an offshore platform within the RPS project-specific winch system for an extended mission duration.

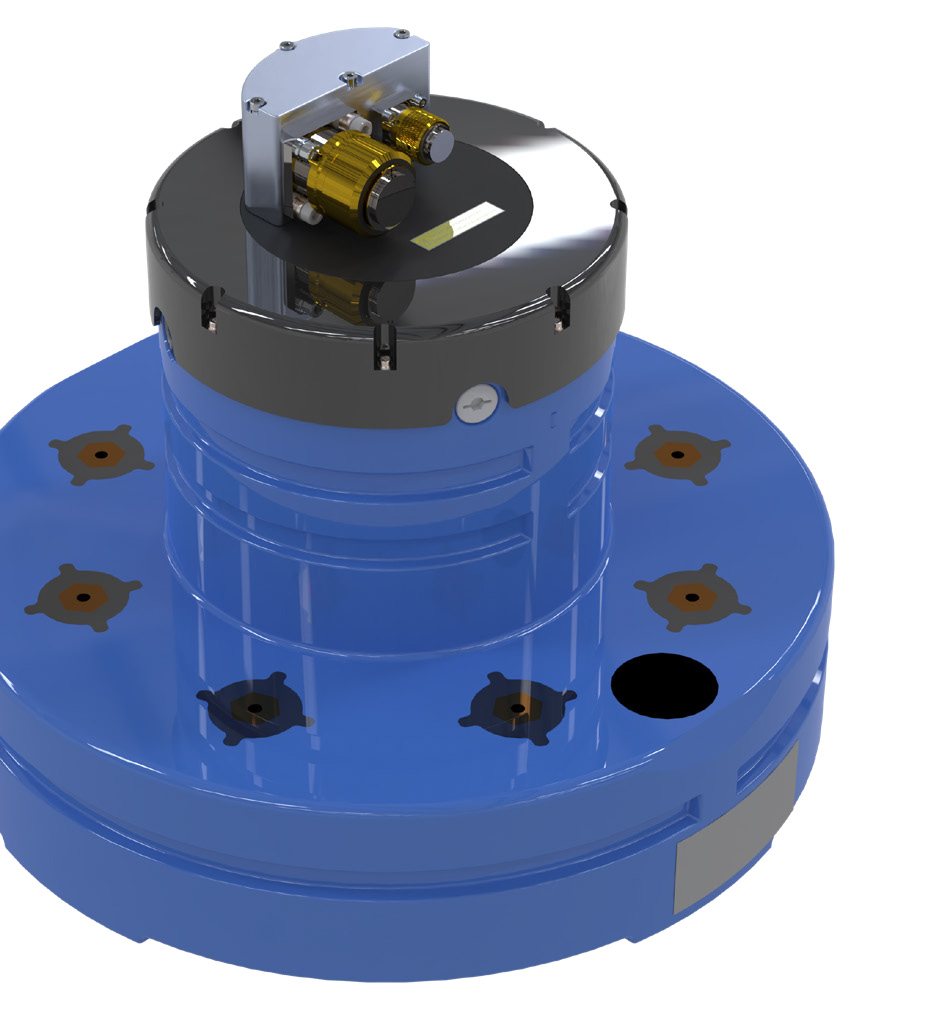

The four independent beams, generated by the phased array transducer inside the Pinnacle, have a much lower acoustic footprint that measures current with a total size smaller than non-phased array systems that only achieve ~1/2 the range. Phased array ADCPs manufactured by RDI are portable and suited for marine environmental assessment, fish-farm monitoring, marine renewable energy projects, hydrographic mapping, and other applications.

Pinnacle ADCP for the Offshore Oil Industry with Deep-Water Profiling and Low Power Consumption

Several advanced capabilities were built into the Pinnacle ADCP, making it an especially adept system for the offshore oil industry. First, it can profile 1,000 meters (far deeper than conventional systems), minimizes power usage, and is built with a low profile to fit in tighter spaces. This is essential since deep-water activity around rigs is often restricted due to a lack of space and the need to minimize power use and equipment weight.

The Pinnacle’s data-gathering capabilities – evaluating current profiles and backscatter – are essential to understanding current profiles in deep water up to four to five kilometers in the Gulf of Mexico. On oil rigs, it becomes all about optimizing space and minimizing power use and weight, as rigs are comprised of steel and typically 300-plus feet high, with as many as seven levels indoors. An essential advantage of the Pinnacle is its diminutive size (half the diameter of many standard ADCPs) and lower cost so that it can be implemented on an oil rig in a manageable and affordable manner.

The system’s versatility means it can be deployed on multiple maritime applications – from buoys to boats to rigs – providing the operator the flexibility to work in challenging environments.

The fourth beam functions as an extra level of redundancy in current measurements

One of its other standout features is its four-beam current-measuring system, compared to the conventional three-beam system in standard ADCPs. The fourth beam functions as an extra level of redundancy in current measurements, vital for operational safety in offshore oil platforms where currents are being measured and the environment is highly dynamic.

The Pinnacle ADCP is also designed with fail-safe redundancy to provide secure physical storage with redundant data availability. If one part of the primary memory system fails, the stored data will remain securely available for immediate retrieval and analysis.

The Pinnacle ADCP is also designed with fail-safe redundancy to provide secure physical storage with redundant data availability. If one part of the primary memory system fails, the stored data will remain securely available for immediate retrieval and analysis.

The system includes MicroSD memory cards. Storing the data on a main memory card is a secure, reliable way to store large volumes of data that can be retrieved and analyzed for timely decision-making based on the foreboding conditions of the moment.

Besides data storage, monitoring tools can alert users to potential health issues, helping third-party modules detect any leaks or possible failures. The system’s advanced features ensure that users know the conditions of the system so they can continue to rely on it to capture their valuable data in a harsh environment. The higher level of sophistication with fail-safe redundancy ensures that the challenges mentioned above to obtaining valuable and reliable oceanographic data would be diminished and minimized through the operational life of the Pinnacle ADCP deployed in a harsh and challenging offshore environment.

The Pinnacle ADCP is designed to deliver high-quality data in high-noise environments

The Pinnacle ADCP is also designed for high-noise environments and can still provide high-quality data amid DP thruster noise on drill ships. Other features, such as the system’s optional phased array add-on, extend the range by 40 percent and make the buoy ideal for deep water where extended profiling is necessary.

To maximize high-level productivity in these operations, the Pinnacle ADCP demonstrates adaptability and iterability. It provides a high-tech solution in a small, affordable, field-sturdy package that is a critical tool for safe, effective rig operations.

To maximize high-level productivity in these operations, the Pinnacle ADCP demonstrates adaptability and iterability. It provides a high-tech solution in a small, affordable, field-sturdy package that is a critical tool for safe, effective rig operations.

The sensor’s ability to provide immediate, high-quality data about rig performance and the safety of rig personnel stands to alleviate the challenge of operating safely in deep water as conventional deposits dwindle and oil operations venture into more extreme environments, again becoming less accessible. The Pinnacle ADCP’s petroleum technology can help ensure these operations remain productive and safe.

Thanks to its high reliability and low operation cost, the Pinnacle ADCP is poised to meet the increasing demand of the offshore oil sector. As it reaches ever deeper waters and more challenging environmental conditions, the Pinnacle will continue to play an essential role in keeping those oil platforms safe.

Thanks to its high reliability and low operation cost, the Pinnacle ADCP is poised to meet the increasing demand of the offshore oil sector. As it reaches ever deeper waters and more challenging environmental conditions, the Pinnacle will continue to play an essential role in keeping those oil platforms safe.