The Overview:

Crucial to the end-user, power distribution technology is where the energy delivered by utilities meets the customer. When energy leaves a utility, it travels over transmission lines, which deliver power to substations. From there, power goes to the switchgear, which directs the flowing energy to its desired endpoint—the end-user. The power distribution technology is mostly about controlling the electrical energy path and delivering it safely and reliably.

Since 1984, Valquest Systems, Inc. has been a leader in power distribution technology. Because their operations depend heavily on electro-mechanical enclosures, specialized cables, and custom solutions, they have made

Teledyne Interconnect Cable Solutions their preferred provider. Reliably and safely delivering power to the end-user is the goal of power distribution technology.

Since 1984, Valquest Systems, Inc. has been a leader in power distribution technology. Because their operations depend heavily on electro-mechanical enclosures, specialized cables, and custom solutions, they have made

Teledyne Interconnect Cable Solutions their preferred provider. Reliably and safely delivering power to the end-user is the goal of power distribution technology.

Demand increases with population growth. The challenging physical demands on cables and the need for dependable power highlight an area where Valquest and Teledyne consistently surpass expectations.

The Challenge:

Valquest Systems had

several essential and non-negotiable requirements. They needed robust, sustainable cables to ensure performance under significant physical stresses and extreme weather conditions. They had to accomplish several things:

- The cables had to work under sustained physical stress, which means no cracking or fraying; this had to hold true under all conditions.

- They had to work in a temperature range of -50° to 70° Celsius. Despite the challenges of extreme heat and exposure to the sun’s ultraviolet rays, the team needed to complete a sustainable cable design for solar energy systems.

- They also needed to ensure the cables could withstand condensation and chemical corrosion.

Working with the Teledyne Interconnect engineering team, Valquest had to secure a design that would meet these requirements effectively as a vital and sustainable part of the overall system.

The Solution:

Teledyne Interconnect understood Valquest Systems’ need for enhanced custom solutions and accepted the challenge of creating tough cables for them.

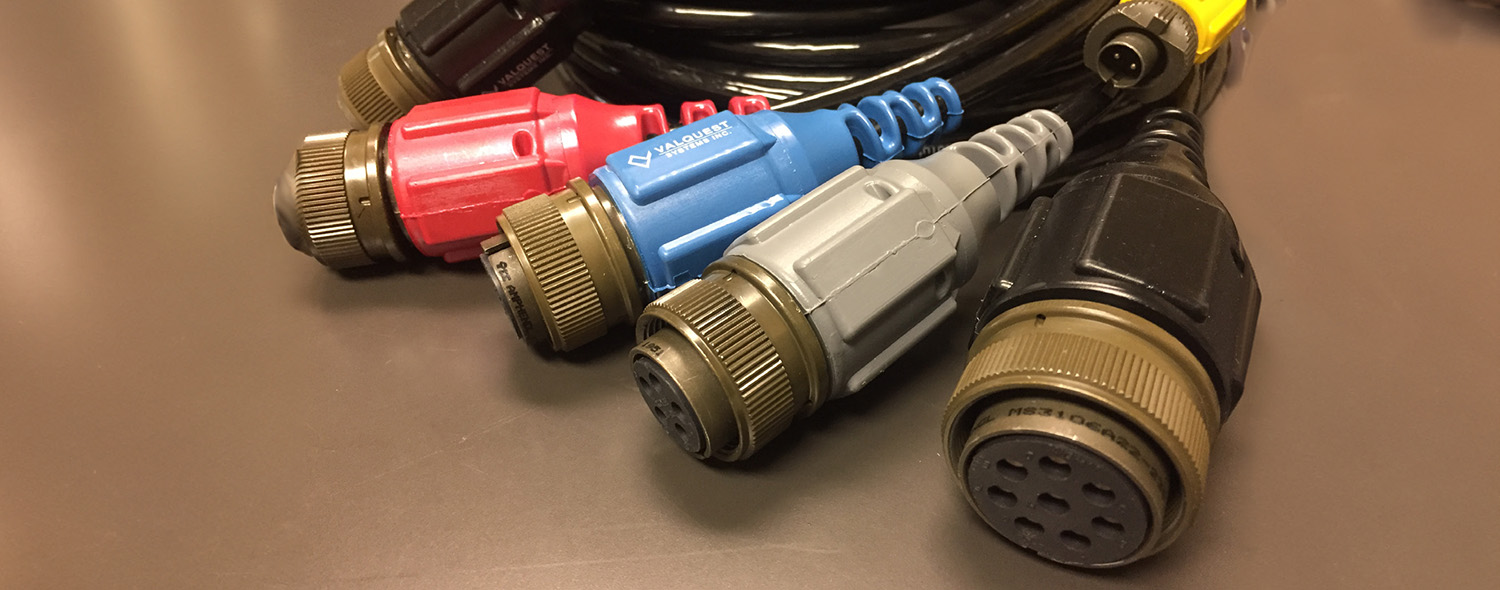

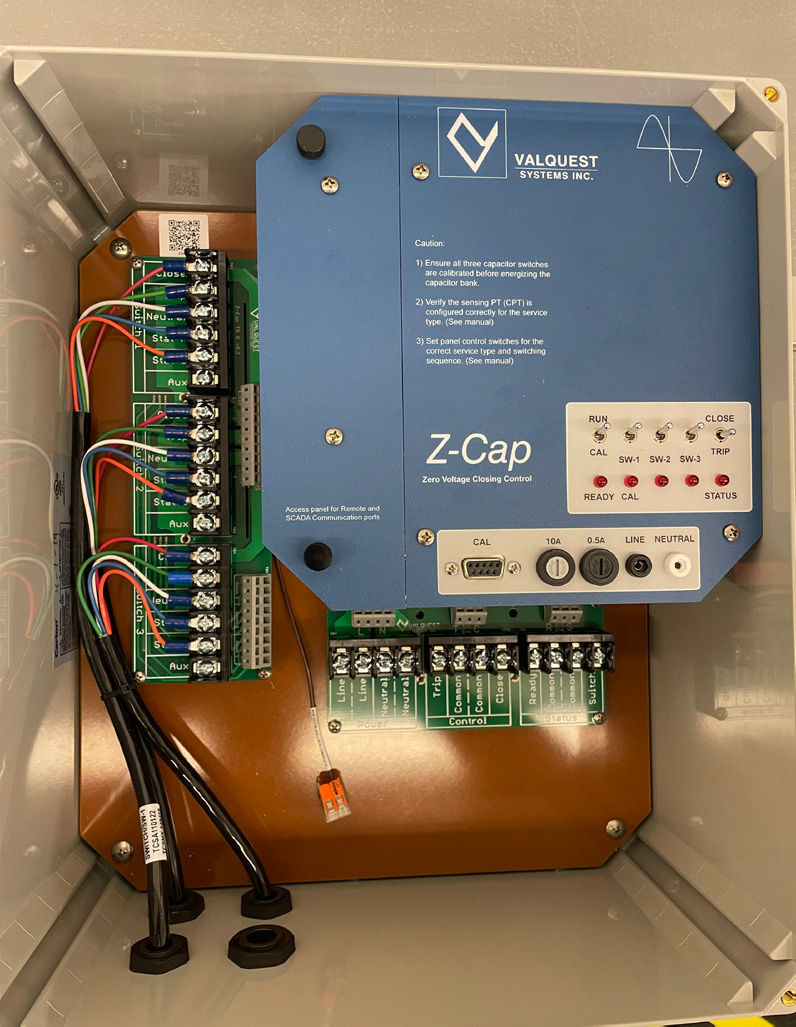

The end product is a suite of four rugged cables designed for applications in extreme physical environments like Alaska and Canada. The cables connect several types of equipment used by Valquest in those harsh locations: they ensure reliable data and power paths to a range of field devices, from junction boxes to various kinds of sensors and armored assemblies. The cables, in effect, hold together a Valquest system in a way that keeps the system operable even as the system components are put to the test by Mother Nature.

“Valquest Systems has been dealing with a lot of issues. All of that has changed since we started working with Teledyne. We’ve never had a failure with Teledyne cables. And you can see why if you look closely. Teledyne’s over-molding is so good that you can hardly even see it. They’re well-made and able to operate under the most challenging conditions we put them in. This had truly been a game changer,” said Tim Dietrich, Vice President, Valquest Systems.

The joint efforts of

Teledyne Interconnect and Valquest Systems have been very successful and have greatly boosted the reliability and performance of Valquest Systems’ power distribution systems. As Valquest develops new products, Teledyne Interconnect keeps developing new cables and solutions to ensure its innovations can power up. These two companies work well together, and the clear reason is that good solutions are necessary when working in an environment where Valquest and Teledyne function.

At Teledyne Interconnect, we are proud to offer the kind of partnership for which we are best known - custom-engineered, industry-specific solutions that work in a pinch, for all sorts of industries. We specialize in cable and interconnect solutions for land, water, air, and space.