High resolution structural inspection of flooded tunnel using BlueView T2250 360°Multibeam Profiling Sonar and Teledyne PDS

High resolution structural inspection of flooded tunnel using BlueView T2250 360°Multibeam Profiling Sonar and Teledyne PDS

Acquiring accurate data on the structural integrity of submerged tunnels, as well as shafts and underwater caverns, has long been a challenging and costly problem for water companies, hydroelectric schemes and mine operators alike. While dewatering of tunnels is one option this can cause additional stress which can cause harm to such assets thereby compounding the problem. Dewatering can also be a costly process to undertake and may also lead to loss of productivity in some circumstances. While

Remotely Operated Vehicles (ROVs) have been used for some years to gather visual and sonar data inside tunnels, visual

(camera) data is often incomplete or inconclusive due to poor visibility caused by turbidity.

The collection of 3D data using sonar technology is often more beneficial as it allows accurate profile data of the tunnel to be acquired.

Single beam scanning sonars are typically used to provide line profiles at periodic intervals. To do this the ROV must be held in position while each discrete scan is conducted. Additionally a continuous spiral/corkscrew profile may be obtained if the sonar is continuously moved through the tunnel however coverage is limited and there is a risk that areas of interest may be missed.

Where high resolution multibeam echo sounders have occasionally been used, their size and cost has often been prohibitive as several multibeam heads have to be integrated to give full 360 degree coverage. This in turn means a larger vehicle must be employed often introducing new challenges of its own.

Enter

BlueView’s T2250 multibeam profiling sonar, a compact turnkey system specifically designed to produce high density 3D data to centimetric accuracy. Utilizing high frequency, low power acoustic multibeam technology, the system uses 2100 overlapping narrow beams to create a continuous 360° profile which is streamed to Teledyne PDS software at a frequency of over 20Hz creating a dense 3D point cloud from which a truly detailed analysis of the health of a structure can be made. Designed for use on ROVs but with a built in data logger making AUV deployment equally straight forward, the T2250 allows inspection companies to use existing ROV technologies to map tunnels in fine detail without the risks associated with dewatering. One such company, Loxus Technologies of Finland put their new 360 degree multibeam profiler to the test...

Enter

BlueView’s T2250 multibeam profiling sonar, a compact turnkey system specifically designed to produce high density 3D data to centimetric accuracy. Utilizing high frequency, low power acoustic multibeam technology, the system uses 2100 overlapping narrow beams to create a continuous 360° profile which is streamed to Teledyne PDS software at a frequency of over 20Hz creating a dense 3D point cloud from which a truly detailed analysis of the health of a structure can be made. Designed for use on ROVs but with a built in data logger making AUV deployment equally straight forward, the T2250 allows inspection companies to use existing ROV technologies to map tunnels in fine detail without the risks associated with dewatering. One such company, Loxus Technologies of Finland put their new 360 degree multibeam profiler to the test...

The ROV is driven down access shaft to the entry point of flooded tunnel

|

Careful organisation was required for tunnel entry Careful organisation was required for tunnel entry

|

Ensuring Integrity of Finland's Päijänne Water Tunnel: ROVs and BlueView Sonar Enable Remote, High-Resolution Inspections Without Dewatering

The Päijänne Water Tunnel in Southern Finland is the world’s second largest tunnel being some 120km in length. The tunnel has a cross section of 16m2 and enables a water flow of 10 cubic metres per second. Completed in 1982 the tunnel cuts some 30-100m below the surface under the bed rock to supply drinking water from Lake Päijänne to over one million people in the greater Helsinki area.

In recent years, repairs had been completed in parts of the tunnel but due to the challenging access to these sites, inspections to check the integrity and longevity of these repairs had not be conducted. Periodic inspection is critical however to ensure integrity of the tunnel and prevent any further collapse. Acquiring accurate high density 3D data without dewatering was clearly very advantageous as it allowed for structural integrity assessment to be conducted without the cost and risk associated with dewatering.

Tunnel access point and Work Site location Tunnel access point and Work Site location |

ROV transportation to deployment area inside the tunnel ROV transportation to deployment area inside the tunnel |

The vehicle selected for the mission was a SUB-Fighter 15k vehicle from Norwegian ROV manufacturer Sperre. With vectored thrusters the vehicle is highly maneuverable and in this instance was equipped with >7000m of tether over which communications could be made to/from a control cabin on surface. The vehicle was used to transport the

Teledyne BlueView T2250 360 degree multibeam profiling sonar through the tunnel to collect 3D point cloud data and sonar imagery in

Teledyne PDS throughout the transit along with a visual record from the ROV cameras.

The work was challenging as tunnel access points are up to 10km apart and some had steep turns in them making launch and recovery a logistical challenge. The remote access points also do not provide any facilities, so everything from power supply to sleeping space needed to be shipped in to each work site before work could begin!

The ROV operated at a slow pace due to the distances it was required to travel. The further it went into the tunnel, the slower it went due to drag. The return trip was even slower and precise piloting was required to reduce the risk of ROV breakdowns in the tunnel. Having to retrieve the ROV inside the tunnel would have been an unwelcome challenge due to the distance, water flow and access limitations. Profile and point cloud data were displayed real-time in the ROV cabin giving additional input to the pilot and further improving situational awareness in low visibility. Positioning information was also input directly to PDS ensuring precise location of any anomalies would be known (standard ROV supplied heading, roll, pitch and depth, sensors were combined with a precise cable counter manufactured by

Teledyne RESON).

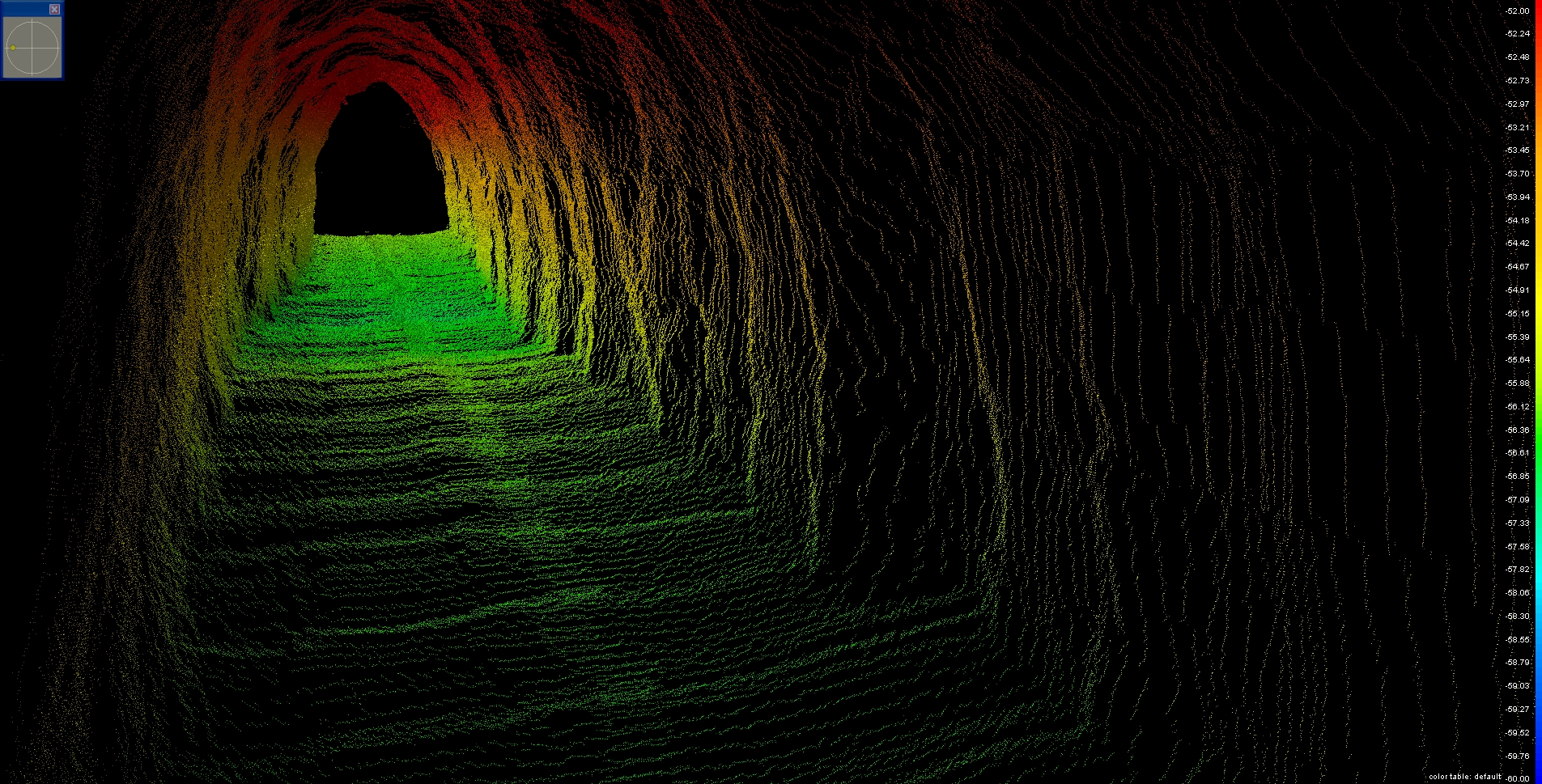

3D profile data image showing the solid integrity of the tunnel

3D profile data image showing the solid integrity of the tunnel

Results

The tunnel was inspected without dewatering. A dense high resolution point cloud was created allowing engineers to take accurate measurements in all three planes from which an assessment of structural integrity could be made. Even loose rocks as small as 20-30 centimeters in length were quickly identified in the model (previously such targets might only have been found by trawling through hours of video records).

The tunnel was inspected without dewatering. A dense high resolution point cloud was created allowing engineers to take accurate measurements in all three planes from which an assessment of structural integrity could be made. Even loose rocks as small as 20-30 centimeters in length were quickly identified in the model (previously such targets might only have been found by trawling through hours of video records).

The 3D data set was detailed and comprehensive thanks to the high update rate, beam density and spatial resolution of the

T2250 360 degree multibeam profiler. The use of the multibeam profiler gave considerably more information on the tunnel’s characteristics than single beam scanning sonars might have in the past and also made for faster data acquisition. Its small size allowed it to be integrated on an existing underwater inspection vehicle. Profiler measurements were displayed and recorded in real time, aiding piloting of the ROV while providing a permanent 3D data set for subsequent analysis. Teledyne PDS was used for 3D online visualization combined with several utility views to aid the ROV operator. Offline analysis has been done using

PDS Processing utilizing the 3D editing possibilities that PDS provides.

The quality of previous repair work was assured and structural integrity was shown to be sound at the time of inspection allowing the client to maintain their routine operations. Water flow could even be increased without damaging the tunnel.

Tunnel inspection operations and control point on the Work Site

|

360° tunnel inspection data seen in

Teledyne PDS

|